Engineering Critical Process Equipment

ASME, ISO, IBR certified fabrication for Oil & Gas, Chemical Processing, Fertilizer, Pharmaceutical, and Petrochemical industries.

ASME, ISO, IBR certified fabrication for Oil & Gas, Chemical Processing, Fertilizer, Pharmaceutical, and Petrochemical industries.

Precision-engineered solutions for critical industrial applications

Shell & Tube heat exchangers engineered for high-pressure, high-temperature applications. Materials: Carbon Steel, Low-Temperature Carbon Steel, Stainless Steel, Duplex, and exotic alloys.

ASME Section VIII Div. 1 & 2 pressure vessels designed to customer specifications and process requirements. Full design validation including stress analysis.

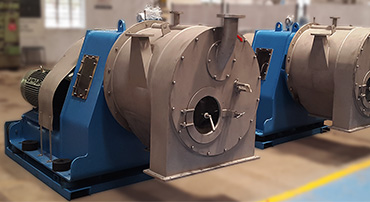

Continuous-operation pusher centrifuges with mechanical and hydraulic drive systems. Engineered for medium to high-capacity solid-liquid separation.

Vertical basket centrifuges optimized for cost-effective solid-liquid separation. High output rates with minimal maintenance requirements.

Custom-engineered automated washing systems for railway rolling stock, commercial vehicles, and fleet operations.

In need of tailor-made process equipment? Talk to our industry experts and let them help you ascertain the best solution to meet your requirements!

Authorized pressure vessel and boiler fabrication per ASME Boiler & Pressure Vessel Code

Quality management systems certified for design and manufacturing processes

Approved manufacturer for IBR-regulated pressure equipment and vessels

Oriental Manufacturers established as a division of Oriental Enterprise Private Limited, focusing on critical process equipment fabrication.

Obtained ASME U stamp authorization, enabling pressure vessel fabrication for international markets.

Expanded manufacturing operations to 32-acre facility in Ranoli, Gujarat, with proximity to major transportation hubs.

Achieved ASME U2 and R stamp certifications, expanding capabilities for high-pressure and nuclear applications.

500+ projects delivered across Oil & Gas, Chemical, Fertilizer, Pharmaceutical, and Petrochemical sectors worldwide.

Our engineering team evaluates process parameters, material specifications, and compliance requirements to deliver equipment that meets your operational needs.

Submit Technical Inquiry